During tests carried out in the high temperature flow facility operated by UK-based S&C Thermofluids, Reaction Engines and Rolls Royce have successfully demonstrated the running at Mach 3.5 conditions of a propulsion solution combining the former’s advanced heat exchanger unit and a modified GNOME engine from the second.

This stage of the tests means the experimental system has now matched the maximum known airspeed record set by the SR-71 Blackbird, the world’s fastest aircraft powered by an air-breathing engine. The combined precooler-engine solution is representative of a propulsion configuration for an unpiloted, reusable high-Mach air vehicle.

The companies have not named the system in their press release, but this is understood to be targeted at the UK Hypersonic Air Vehicle Experimental Program (HVX), a program that was launched at Farnborough in 2022 as a cooperation between DSTL, Reaction Engines, Rolls-Royce, the Royal Air Force’s Rapid Capabilities Office and the UK’s National Security Strategic Investment Fund.

Earlier still, in 2019, the UK MOD had given the two firms £10 million to support research into the potential increase in performances and reliability of an air-breathing engine fitted with technology derived from Reaction Engines’s precooler. At the time, the engine considered was the EJ200.

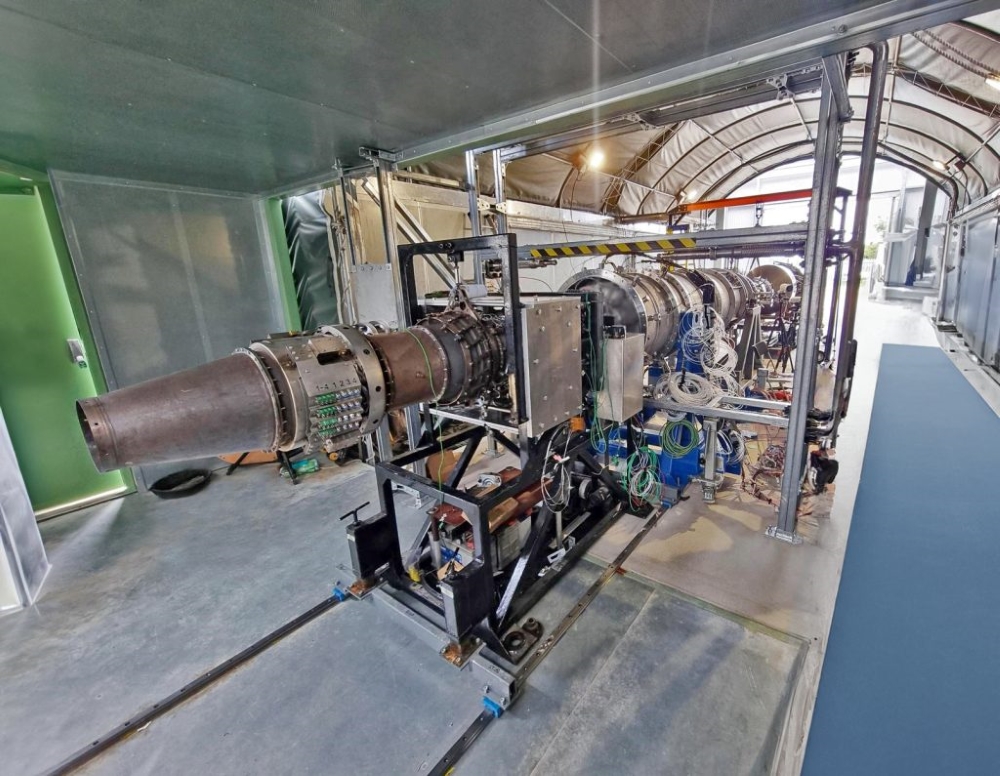

The current campaign of tests uses a heavily modified Rolls Royce GNOME: the original turboshaft engine has been converted into a gas generator in the rig by removing the power turbine and modifying the nozzle guide vanes. This is the first time the precooler is fully integrated with an engine, which requires a solid and reliable coupling between the heat-exchanger and the fan face of the compressor inlet, so the downstream flow from the heat exchanger does not cause damage or instabilities.

The pre-cooler and gas turbine core integrated in this way would be used to propel an air vehicle from a standing start on the ground to a transition speed of over Mach 3 upon which the turbine would have to be cooconed so thrust can be provided by a ramjet/ramburner instead, for further acceleration to Mach 5 and beyond.

The precooler itself was earlier demonstrated at Mach 5 conditions in a test campaign in Colorado in 2019, but as a stand-alone unit with no engine integrated. The heated air for that test was generated using a General Electric J79 in maximum afterburner, blowing straight into the heat exchanger. The precooler is made up of 16,800 thin-walled tubes through which helium is pumped to remove heat. In the Mach 5 test, the system reduced air temperature from 1,000C to roughly 100C in less than 1/20th of a second.

As exemplified by the recent test with a modified GNOME, the pre-cooler enables air-breathing engines to operate far beyond their original design points.