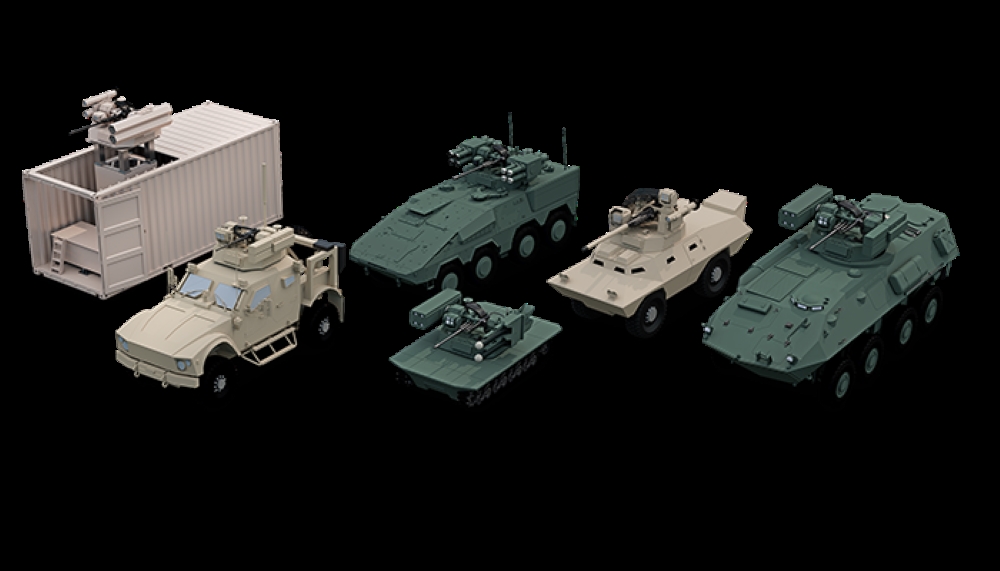

Moog recently showcased its Reconfigurable Integrated-weapons Platform (RIwP) at the Defence Vehicle Demonstration (DVD) 2024 event in the UK, emphasizing its capabilities for the British Army's Ground Based Air Defence (GBAD) requirements.

Moog presented two configurations, namely a SHORAD (Short-Range Air Defence) variant mounted on a British Army RIDGBACK 4x4 protected mobility vehicle, and a 1/3 scale model in an anti-armour 'overwatch' configuration. Both variants feature a 30x113mm main gun and an M240 7.62mm machine gun. The SHORAD configuration mounts missile canisters for the in-service High Velocity Missile (HVM) and the Lightweight Multirole Missile (LMM), while the overwatch configuration is characterised by twin dual-BRIMSTONE rails.

Thanks to a conversation with Richard Allen-Miles, EMEA Capture Lead at Moog, FW MAG offers some insights into Moog’s spearhead product and related development strategies.

FW MAG: How the presence of Moog in the UK with your Reconfigurable Integrated-weapons Platform (RIwP) matches with your plans and ambitions for this product?

Richard Allen-Miles: Moog recognises the need to add resilience to our production capabilities and global supply chain by establishing manufacturing bases worldwide. In the case of RIwP, frequently the purchase of weapon systems by any armed force or government requires minimum levels of local content and that is certainly the case in the UK. Establishing a UK manufacturing base and supply chain for RIwP is made significantly easier by the fact that Moog has been operating here since the 1960s and is currently supplying technology on British military programmes as diverse as F-35 and TYPHOON aircraft, AJAX and CHALLENGER III land platforms, and ASTUTE- and DREADNOUGHT-class submarines. Setting up a UK manufacturing base for RIwP therefore requires equipping of space inside an existing Moog facility and leveraging existing UK supply chains. Furthermore, this UK base will be used to support export activity in the EMEA region.

FW MAG: A successful product is often the result of a trade-off between proven solutions and novel technologies. What base technologies are reliable and proven and which ones are innovative in the Reconfigurable Integrated-weapons Platform (RIwP)?

Richard Allen-Miles: Almost all of the components and subsystems within RIwP are designed and manufactured by Moog. This is unique for a weapons system manufacturer (typically key components are bought in) and allows Moog to offer unparalleled insight and support. Proven technologies include all of our turret sub-system LRUs (actuators, motor controllers, slip ring, etc) as well as our stabilisation software. Moog actuation and stabilisation systems have been used on turrets and weapon stations worldwide for over 40 years. Novel technologies include a common system and software architecture which allows interchange of sensors and effectors while keeping the same base assembly and core fire control. By the way, RIwP as a system is already fielded with the US Army, so at the system level it is proven and reliable.

FW MAG: The RIwP features pre-planned mechanical, electrical, and software interfaces that facilitate the swapping of payloads (ballistic guns, missiles, sensors). Can you illustrate/explain to our readers the development pathway of such a capability?

Richard Allen-Miles: The pathway to RIwP was a realisation that bespoke weapon systems can’t keep up with an ever-changing threat. Both cost and development times prohibit the supply of an effective custom solution for a point-in-time technical adversary. Users today need the ability to adapt/grow as the threat landscape changes without starting from scratch each time.

FW MAG: From your point of view, what trends do you see shaping the future weapon systems for military vehicles? What will be your role to play?

Richard Allen-Miles: From the point of view of weapon systems, we believe that RIwP is at the vanguard of next-generation capabilities. Defence companies worldwide have spent decades improving performance and capabilities of weapons and sensors, whereas the launchers that they are fitted to or launched from have remained fundamentally the same as they were 50 years ago. Our enemies are now able to deploy capabilities and evolve technologies at a pace that traditional procurement cycles and weapon systems cannot hope to keep pace with. For this reason, it is vital that our armed forces acquire and deploy weapon systems that allow them to add and modify weapons as new threats emerge and/or as missions change. There is also a budgetary driver here: the reality is that few defence ministries can afford to procure the weapon systems they would like to have (if money were no object). RIwP allows users to field a system that although initially fitted with sensors and weapons that met budget availability at that time can be modified in future as new budgets become available. An example of such a situation would be an initial configuration that had just a cannon and a gunner’s sight but that then had missile(s) fitted at a later date once funding for those could be secured. Any other weapon system would always be confined to and limited by the sensors and weapons originally fitted to it, but RIwP overcomes this with its future-proofed, flexible design.

FW MAG: Thank you for your insights!

Follow us on Telegram and Facebook.