At Euronaval, Kongsberg Maritime emphasized propulsion as a crucial aspect of naval capability, and showcased products that combine decades of operational experience with the latest advancements in hydrodynamics.

Kongsberg Maritime has been at the forefront of developing advanced propulsion technologies that cater to both civil and military maritime sectors. Their innovative systems, such as the PROMAS propeller and rudder system, have demonstrated significant improvements in fuel efficiency, offering up to 6% better performance compared to conventional systems for military vessels.

Patrik Kron, Chief of Naval Systems & Naval Sales for Kongsberg Maritime, told FW MAG that “historically, naval forces have not prioritized fuel consumption in their operational considerations. However, the landscape is changing as navies increasingly focus on extending operational ranges and improving overall efficiency. This shift has sparked growing interest in fuel-saving technologies like Kongsberg's PROMAS system, which has been shown to deliver fuel savings exceeding 5% for naval platforms.”

PROMAS combines the rudder and propeller into a single propulsion system. It features a bulb-rudder design, which differs from the conventional off-centre rudder systems typically used by navies on twin-screw vessels. The PROMAS system has already been implemented on the Belgian research vessel RV Belgica, which entered service in 2022, and has been selected for the latest ship in the United States Coast Guard's new Offshore Patrol Cutter (OPC) HERITAGE Class programme. Specifically, it will be used on the Coast Guard Cutter PICKERING, the fifth ship in the programme.

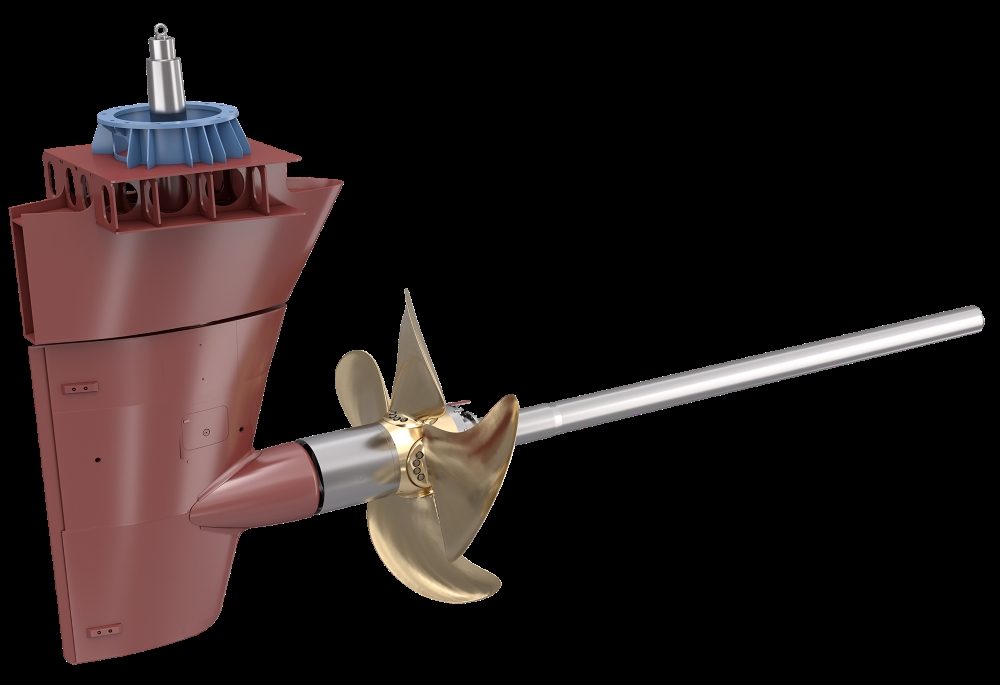

Another key highlight of Euronaval 2024 was the use of Kongsberg Marine’s ELEGANCE propulsion pods as part of a comprehensive propulsion and equipment package for the Italian Navy's new Special and Diving Operations - Submarine Rescue Ship (SDO-SuRS). The propulsion system's core consists of a pair of Kongsberg ELEGANCE propulsion pods, which combine direct electric permanent magnet motor-driven propulsors, an electric power system with batteries and power management, and a hydrodynamic design developed at Kongsberg's Hydrodynamic Research Centre. The ELEGANCE pods offer several advantages, including precise and efficient vessel operation across a wide speed range, quiet operation crucial for submarine rescue missions, low oil content with a double barrier seal for environmental protection, and the ability to operate in fully electric zero-emissions mode in port or for limited offshore operations. To complement the main propulsion system, Kongsberg will also supply three tunnel thrusters for enhanced manoeuvrability, an Mcon propulsion control system, a DP3 (Dynamic Positioning) system for precise station-keeping, and single and multibeam echo sounders for underwater sensing.

The ELEGANCE propulsion system is designed to provide optimal efficiency over a large speed range. The permanent magnet electric motors, combined with the hydrodynamic pod design, offer efficient operation at various speeds, reduced carbon emissions, and noiseless operation, which is critical for submarine rescue operations.

Patrik Kron explained that “the development of these advanced propulsion systems has been largely driven by the commercial maritime sector, particularly the cruise ship industry. This sector's early adoption of fuel-efficient technologies has paved the way for their adaptation to naval applications. Kongsberg has effectively leveraged its experience in the commercial sector to refine and optimize these technologies for military use.”

Furthermore, one of Kongsberg's notable innovations involves the use of 3 propulsors instead of the traditional 2, a configuration that can potentially increase efficiency by up to 10%. This approach, while requiring more complex design and higher initial investment, offers substantial long-term benefits in fuel savings and enhanced operational capabilities.

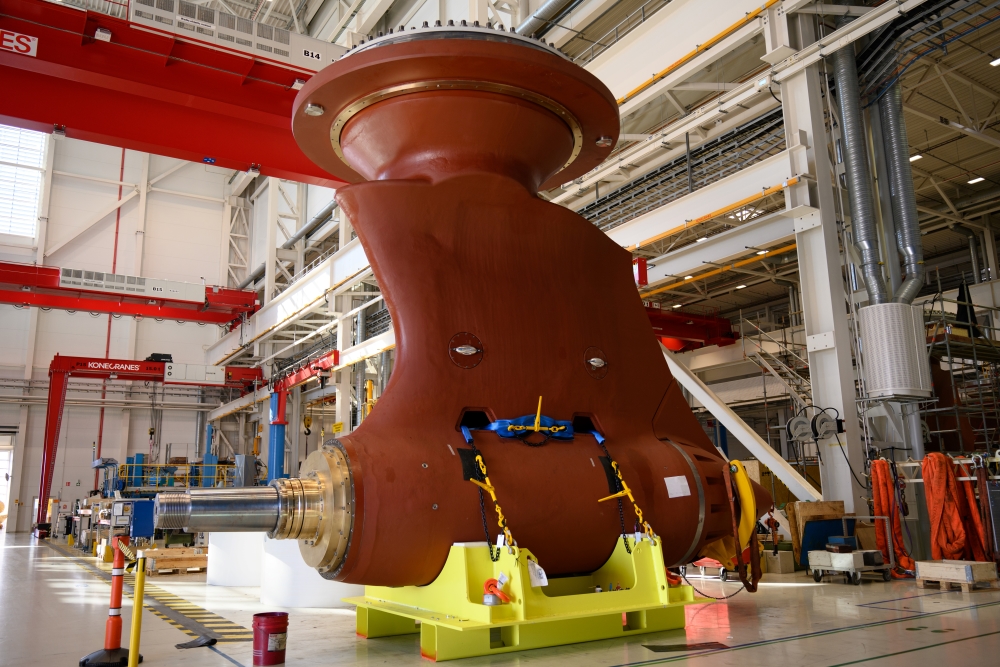

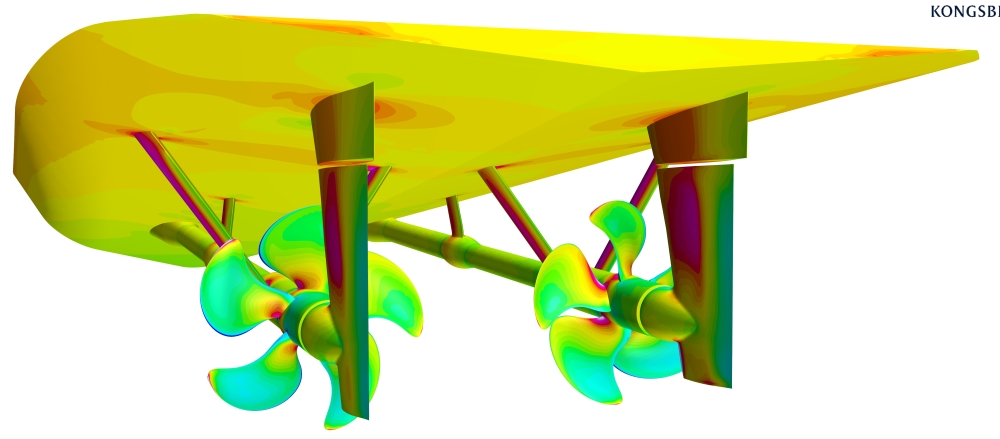

Indeed, Kongsberg Maritime has developed a Hybrid Triple Screw System that combines a conventional propeller shaftline system with twin azimuth/pod thrusters. This system uses a large, centrally aligned shaftline propeller along with two ‘wing’ units, which can be either AZIPULL thrusters or ELEGANCE PODs.

This Hybrid Triple Screw arrangement offers vessels new levels of flexibility and redundancy in their operations. It provides excellent manoeuvrability from the azimuth propulsion while achieving better efficiency and performance during transit at sea with the conventional propeller and shaftline system. Internal studies by Kongsberg have demonstrated that the Hybrid Triple Screw System allows for more efficient thrust creation during all phases of vessel operations. In-house testing by Kongsberg using a Ro-Pax ferry design of 98 m showed that, while underway at a speed of 20 knots, the Triple Screw System has a power requirement 12% less than a twin CPP system.

Results show that this system has less power consumption than either a double CPP (Controllable Pitch Propeller) configuration or a single screw CPP configuration. For example, Scandlines has adopted this Hybrid Triple Screw System on two of its ferries connecting Germany and Denmark. These 170-m ferries, named Berlin and Copenhagen, use twin AZIPULL thrusters of 3500kW on the wings and a central CPP with 9,000kW. This configuration provides fuel savings during transit and allows easier operation in shallow port waters.

Lastly, during Euronaval 2024, Kongsberg Maritime also secured a contract to provide controllable pitch propeller systems for the first ship in the Peruvian Navy's new frigate program. This development is part of the Peruvian Navy's fleet modernization efforts, with the multipurpose frigates set to be constructed in Peru through a collaboration between HD Hyundai Heavy Industries (HD HHI) and state-owned shipbuilder SIMA. The frigates are based on the HD HHI HDF-3200 frigate design, boasting a displacement of 3,400 tonnes, a length of 127 m, and a maximum speed of 26.5 knots. They are engineered for long-range patrol capabilities, with a range of 6,000 nautical miles. Kongsberg Maritime's contract encompasses twin controllable pitch propellers, shaftlines, bearings and seals, and associated control systems.

Follow us on Telegram, Facebook and X.