The fifth edition of Arquus Technoday, held at the Beynes military camp on June 4th, 2025, represented the first major showcase of the Franco-Belgian alliance since John Cockerill Defense completed its acquisition of the French military vehicle manufacturer eleven months earlier.

This year's event demonstrated how the strategic merger between these two defence industry leaders is already yielding concrete technological synergie, as the merger brought together John Cockerill's expertise in light tank turrets and weapon systems with Arquus's century-long heritage in military vehicle manufacturing. At Technoday 2025, the tangible results of this integration were evident throughout the exhibition. The presence of Belgian Cockerill turret systems on iconic French Arquus platforms, including the SCARABEE reconnaissance vehicle, the SHERPA tactical platform, and the venerable VAB armoured personnel carrier, illustrated how the combined entity is already delivering on its promise of integrated solutions. Emmanuel Levacher, Arquus CEO, and Thierry Renaudin, CEO of John Cockerill Defense, presented these developments jointly, symbolizing the operational reality of the merger. Additionally, recent developments indicate that John Cockerill is actively seeking to expand its manufacturing footprint in Belgium. In early 2025, the company expressed interest in acquiring the recently closed Audi Brussels site (Vorst) to establish a new production unit for military vehicles, aligning with the Belgian government’s strategy to bolster domestic defence manufacturing. John Cockerill Defense maintains a major existing facility in Aubange, Belgium, and is actively pursuing the acquisition or transformation of additional major sites.

Two main drivers were identified by Levacher et Renaudin for the company for the months to come.

First, on the Ukrainian battlefield, both sides have suffered heavy losses of tanks and heavily armoured vehicles due to the proliferation of anti-tank guided missiles, artillery, and especially drones. As a result, Ukrainian and Russian forces have adapted by relying more on light vehicles (such as pickup trucks, ATVs, and wheeled armoured personnel carriers) for rapid troop movement, reconnaissance, and hit-and-run tactics. While light vehicles are more vulnerable to certain threats, the rapid evolution of battlefield technologies, such as modular add-on armour and integrated drone countermeasures, mitigates some of these risks. Arquus’s ongoing innovation in these areas, including hybrid propulsion for silent movement and reduced signatures, further enhances the survivability and utility of its vehicles in contested environments. In summary, the lessons of Ukraine have validated Arquus’s focus on light, fast, and highly mobile vehicles.

Second, John Cockerill Defense’s interest in acquiring large production sites from the automotive industry, such as the former Audi Brussels plant or the Caterpillar site in Charleroi, is driven by the need to rapidly scale up armoured vehicle manufacturing in response to Europe’s rearmament. John Cockerill Defense’s move is a calculated response to unprecedented demand for armoured vehicles. The success and economic sustainability of this strategy, however, are directly tied to maintaining high production volumes; without them, the cost advantages and industrial logic of large-scale facilities would quickly erode. Therefore, Renaudin underlined that the major dependency will be the effective procurement of large numbers of vehicles as well as a final alignment on base requirements with Belgian (and in perspective European) armed forces.

Advancing military robotization

The robotization of armed forces emerged as a central theme at Technoday 2025, with Arquus presenting a dynamic demonstration of its DRAILER, a 4x4 modular hybrid robot that represents Arquus's vision for unmanned ground vehicle capabilities. This sophisticated platform, presented for the first time at Eurosatory 2024, embodies the concept of keeping soldiers away from danger while providing essential tactical support through its advanced robotization features. The platform's versatility extends beyond simple transport, with capabilities for mounting weapon systems including the integration of HORNET turrets for direct fire support missions.

The strategic implications of the DRAILER extend beyond the vehicle's features. The system can be employed in teleoperation mode, allowing human operators to control the vehicle remotely for reconnaissance missions, route clearance operations, and logistics support. The DRAILER's modular design enables rapid reconfiguration for diverse mission sets, including electronic warfare, anti-drone operations, indirect fire support, and radio relay functions.

Advances in protective technologies

The evolution of armour protection technologies demonstrated at Technoday 2025 revealed significant advances in materials science and protection system design. Building on years of research and development, Arquus showcased innovations that promise to revolutionize vehicle survivability while addressing the perpetual challenge of weight versus protection trade-offs. The company's approach to protection encompasses both ballistic and blast resistance, with particular emphasis on process optimization, advanced materials development, and innovative assembly techniques.

Recent developments in material hybridization have enabled Arquus engineers to develop armour packages with reduced surface density compared to traditional 500 Brinell armoured steel while maintaining equivalent protection levels. These advances represent fundamental breakthroughs in protection technology, enabling vehicles to achieve superior survivability without the mobility penalties traditionally associated with heavy armour. The practical implications extend beyond individual vehicle performance to encompass strategic mobility, logistics, and deployment considerations that are increasingly critical in modern military operations.

Additive manufacturing technologies have emerged as game-changers in armour development and vehicle design optimization. Arquus demonstrated practical applications of 3D printing technology by producing VAB armoured vehicle doors with 20-25% weight reduction compared to traditional manufacturing methods. While acknowledging that early prototypes revealed some defects, the company has successfully mastered the materials and processes involved, achieving cost-effectiveness that justifies the performance gains. This technological maturation represents a significant milestone in the practical application of additive manufacturing to military vehicle production.

Arquus also showcased the results of the OPTIFAB study, commissioned by the French DGA in 2020, which explores the use of additive manufacturing (3D printing) to optimize anti-blast protections and spare parts for light armoured vehicles (5-10t class). Its main objective is to assess and compare various manufacturing technologies, focusing on how additive manufacturing can create more effective, rapidly produced blast-resistant structures, especially for vehicle floors. By leveraging innovative materials and lattice structures, OPTIFAB aims to accelerate prototype development, enhance protection against explosions, and potentially revolutionize how armoured vehicle components are designed and produced for the French armed forces.

Anti-drone capabilities

The growing threat posed by unmanned aerial systems has driven rapid innovation in counter-drone technologies, with Arquus and its HORNET subsidiary presenting the HORNET Air Guard system. This represents a comprehensive approach to drone defence that integrates detection, jamming, and kinetic engagement capabilities into a single, highly effective platform. This system addresses the complex challenge of countering diverse drone threats through multiple complementary technologies.

The system features a small radar system, which provides drone detection and identification that continuously scans the operational area, ensuring 360-degree coverage while allowing the main weapon station to continue normal observation and combat missions. The detection architecture enables the system to maintain persistent surveillance while the primary turret functions remain uncompromised. Detection systems are mounted on the HORNET's independent smoke grenade launcher ring, allowing for simultaneous operation of multiple sensor types without interference

The system's innovative design can independently mount jammers or integrated radar systems alongside the double-weapon station and the smoke grenade launcher. This configuration enables the embarked system to operate with independent elevation and azimuth control, allowing operators to maintain tracking of one target while engaging another. The system's ability to function across multiple engagement modes simultaneously addresses the challenge of countering sophisticated drone operations that may employ multiple platforms with varying capabilities and operational profiles.

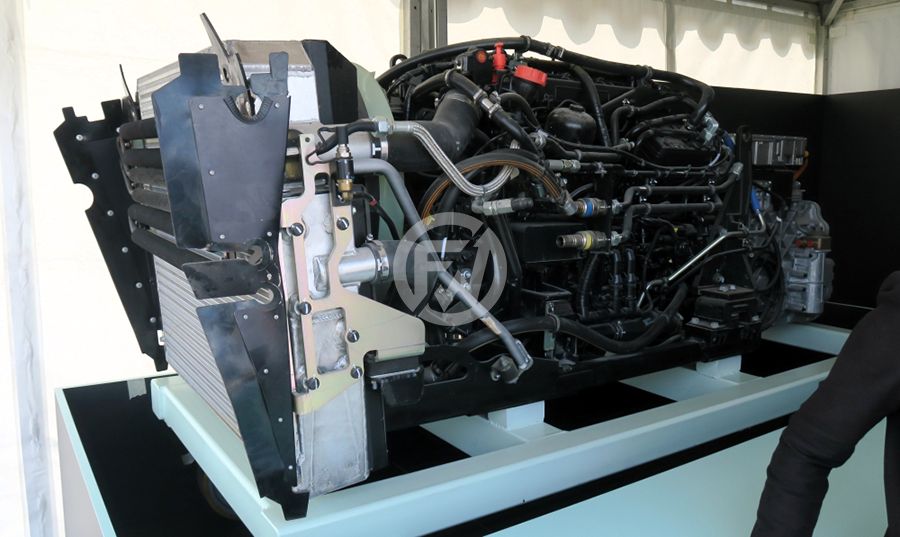

Hybridization and future mobility concepts

The integration of hybrid propulsion technologies emerged as a critical theme throughout Technoday 2025 to provide armed forces with enhanced operational flexibility, reduced logistical footprints, and improved tactical capabilities. Arquus's commitment to hybridization extends across its vehicle portfolio, with the DRAILER robot serving as a tangible demonstration of how hybrid electric propulsion can enhance military effectiveness. The system's ability to operate in silent electric mode for reconnaissance and stealth operations while maintaining conventional propulsion for high-mobility requirements illustrates the tactical advantages of hybrid technologies.

The strategic implications of military vehicle hybridization extend far beyond individual platform performance to encompass fundamental changes in military logistics and operational planning. Hybrid systems offer the potential for dramatically reduced fuel consumption, extended operational ranges, and enhanced stealth capabilities through silent running modes. These advantages translate directly into improved operational security, reduced logistical vulnerabilities, and enhanced tactical flexibility in complex operational environments.

Looking toward future developments, Arquus has announced plans to unveil GRIFFON hybridization capabilities in the spring of 2026. This development represents a significant milestone in the evolution of the French Army's SCORPION program vehicles, potentially providing enhanced capabilities for the GRIFFON and JAGUAR vehicles already in service. The integration of hybrid technologies into proven platforms like the GRIFFON reflects the maturation of these systems from experimental concepts to operationally viable capabilities.

Technological integration and future prospects

The convergence of multiple advanced technologies demonstrated at Technoday 2025 points toward a future where military vehicles serve as integrated platforms for diverse mission requirements rather than single-purpose systems. This holistic approach to technology development ensures that individual innovations contribute to broader capability improvements rather than existing as isolated technological achievements.

Technoday 2025 demonstrated that the merger between Arquus and John Cockerill Defense has moved beyond corporate integration to deliver tangible technological capabilities that enhance military effectiveness. The event showcased breakthrough developments in robotization, armour protection, anti-drone technologies, and hybrid propulsion that collectively represent significant advances in military vehicle capabilities. According to the company’s executives, the success of the Franco-Belgian partnership provides a compelling model for future European defence cooperation, while the demonstrated technologies offer practical solutions to contemporary military challenges ranging from drone threats to operational sustainability. As the partnership continues to mature, the innovations presented at Technoday 2025 suggest that this alliance will play an increasingly important role in shaping the future of European defence capabilities.