At DSEI 2025, the British firm Pearson Engineering has announced the signing of a Memorandum of Understanding with the Ukrainian defence company Ukrainska Bavovna, with the purpose of jointly providing repair and maintenance service for the Pearson Engineering systems already delivered to Kiev, in particular mine-clearing and breaching tools.

The 2 companies will collaborate in delivering training for the users and will explore the possibility of producing Pearson’s kit directly in Ukraine. During 2024, Pearson Engineering exported nearly £60m worth of equipment globally, including supplying specialist mine clearance equipment to Ukraine to support humanitarian demining.

More equipment was gifted in kind by allies of Ukraine, most notably by the UK which, in the run-up to DSEI, announced the signing of an order for 26 new Track Width Mine Ploughs specifically to replace material provided to Kiev. The order, valued at roughly 10.5 million pounds (VAT included) also includes 24 frontend attachment kits to enable the installation of the ploughs on as many CHALLENGER 3 tanks.

Shortly before DSEI, the UK MoD also launched Project ATTILA which envisaged the procurement of up to 6 WARRIOR IFVs converted into remotely operated breaching systems and “demonstrators” to be used to explore the usefulness of large UGVs in a variety of other roles and applications. This follows the success of project WEEVIL, which saw Pearson Engineering demonstrate its BEACON remote control system installed on a WARRIOR. This system, which employs cables to avoid vulnerability to jamming, allows the converted WARRIOR to be operated from some 4 km away. WEEVIL was fitted with a Track Width Mine Plough, a suitably downscaled system to fit the vehicle.

Pearson Engineering believes that UGVs are the best solution to enable NATO forces to appropriately tackle the difficulties and dangers of a major breaching operation through enemy minefields: in order for such operation to be successful, the opening of multiple safe lanes is essential and the removal of the crews from the equation lowers the price in both lives and money.

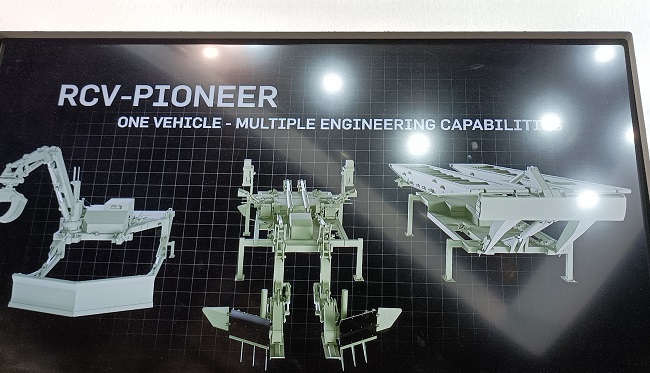

At DSEI, Pearson showcased a large, tracked MRCV by Milrem Robotics fitted with one of its proprietary RCV PIONEER modular capability systems. Specifically, the module on display was the demountable breaching system with front and rear Track Width Mine Ploughs. The rear plough’s main function is to stabilize the UGV and enable the ploughs to be driven into the ground at an appropriate depth. Without the rear plough, at circa 14 tons, the UGV on its own would obviously not have a comparable mass to the large crewed vehicles, often MBT-size, used for these operations and would not be able to dig as deep.

Front and rear ploughs fold upwards atop the vehicle to reduce its shape and volume for transport, and the whole module can quickly be taken off the UGV thanks to adjustable lifting jack legs and container-style attachment points for lifting and transport.

Pearson also offers other RCV PIONEER capability modules, including rollers and rummaging/excavator arm for counter-IED/urban clearance tasks or a bridgelaying module. Apart from the Milrem MRCV, Pearson Engineering has already worked extensively also with the General Dynamics TRX, very similar in concept and overall shape, field testing the PIONEER Urban Clearance module on it.